冷轧轧制油泵吸油管路用绕性橡胶伸缩膨胀节

选对膨胀节, your equipment’s best friend

In the world of industrial applications, the humble expansion joint is often the unsung hero. While it may not be the flashy component on the radar, it plays a critical role in safeguarding your equipment from vibrations, pressure fluctuations, and the stresses that come with heavy machinery and high-pressure systems.

Expansion joints are essential in oil pump systems, where they help absorb the compressive and tensile stresses that occur when fluids enter and exit the pump. Without them, the internal pressure changes could cause everything from pipe fatigue to catastrophic leaks. But the right expansion joint can make all the difference.

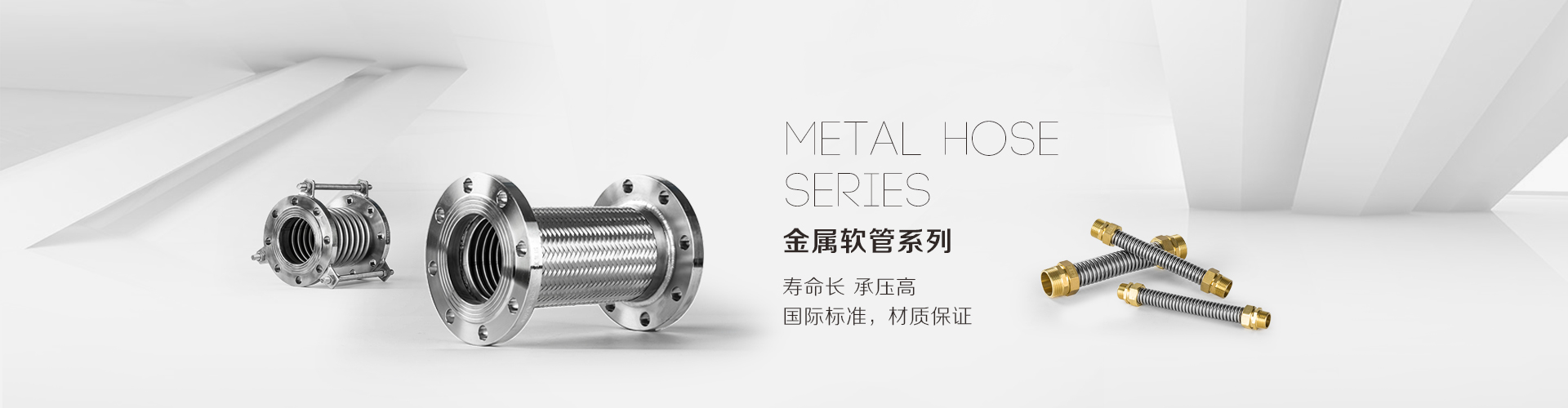

There are several types of expansion joints, each suited to different applications. Bellows, for instance, are a common type, offering excellent energy absorption. These are typically made from materials like rubber or metal and are ideal for systems with moderate pressure and fluctuating temperatures. However, when dealing with high-pressure oil pumps, bellows may not be sufficient.

Spiral-wound metal bellows, or coil type expanders, are a more robust choice for high-pressure applications. They consist of a series of spiral-wound metal pleats that can absorb significant pressure changes without deforming. These are often used in industrial settings where the equipment is subjected to harsh conditions. However, they can be heavier and more expensive than bellows, so cost and weight considerations are important.

For systems that require a combination of flexibility, durability, and resistance to environmental factors like temperature fluctuations and chemical attack, spiral-wbbbb metal bellows with a triple-coil design are an excellent choice. These offer the best of both worlds, combining the flexibility of spiral-wound expanders with the durability of a multi-layer construction.

But what makes a spiral-wound metal bellows the best choice for oil pump applications? The spiral-wound design allows for a high degree of flexibility, which is essential for absorbing the compressive and tensile stresses that occur when fluid flows in and out of the pump. The material, typically a high-strength metal or steel, is resistant to wear and tear, and the triple-coil design provides a high energy absorption capacity, which is critical for protecting the equipment from pressure surges.

Moreover, spiral-wound metal bellows are relatively easy to install and maintain. They come in a range of sizes and can be customized to meet the specific needs of your application. The design is also compact, making them ideal for space-constrained environments.

When choosing an expansion joint for your oil pump system, it's important to consider the operating conditions. High-pressure, high-temperature, and chemical resistance are key factors to look for. A spiral-wound metal bellows with triple-coil design is a safe bet for these conditions, offering a reliable and durable solution.

In conclusion, while expansion joints may not be the first thing you think of when it comes to industrial equipment, they are an indispensable component that can make a world of difference. The right expansion joint can protect your equipment from the stresses of operation, extending its lifespan and ensuring optimal performance. So, when selecting an expansion joint for your oil pump system, take the time to consider the options available, and choose the one that best suits your needs.

上一篇:环保型锅炉用柔性橡胶接管

下一篇:自来水加压泵站用饶性膨胀节